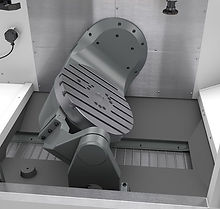

2026 HAAS UMC-750 - 5 Axis Machining Center

-

5-axis simultaneous machining

-

Powerful inline direct-drive spindle

-

Large capacity side-mount tool changer

-

Includes Wireless Intuitive Probing System

5-axis machining is an effective means to reduce setups and increase accuracy for multi-sided and complex parts. The Haas UMC Series universal machining centers are cost-effective solutions for 3+2 machining and simultaneous 5-axis machining. The UMC-750 has an integrated dual-axis trunnion table with a 500 mm diameter platter that features standard T-slots and a precision pilot bore for fixturing versatility. The trunnion provides +120 and -35 degrees of tilt and 360 degrees of rotation to provide excellent tool clearance and large part capacity.

2024 HAAS VF5/40 XT-4 AXIS VERTICAL MILL

Vertical Machining Center; 60" x 26" x 25" (1524 x 660 x 635 mm), 40 taper, 30 hp (22.4 kW) vector drive, 10,000 rpm, inline direct-drive, 50+1 side-mount tool changer, 600 ipm (15.2 m/min) rapids, automatic chip auger, programmable coolant nozzle, color remote jog handle, power-failure detection module, 1 GB program memory, 15" color LCD monitor, USB port, memory lock key switch, rigid tapping and 95-gallon (360 liter) flood coolant system, and last but not least state of art Renishaw probing for most accurate machining

2022 HAAS VF7/40- 4 Axis Capability

Vertical Machining Center; 84" x 32" x 30" (2134 x 813 x 762 mm), 40 taper, 30 hp (22.4 kW) vector drive, 10,000 rpm, inline direct-drive, 50+1 side-mount tool changer, 600 ipm (15.2 m/min) rapids, automatic chip auger, programmable coolant nozzle, color remote jog handle, power-failure detection module, 1 GB program memory, 15" color LCD monitor, USB port, memory lock key switch, rigid tapping and 95-gallon (360 liter) flood coolant system, and last but not least state of art Renishaw probing for most accurate machining

2022 HAAS VF4/40

Vertical Machining Center; 50" x 20" x 25" (1270 x 508 x 635 mm), 40 taper, 30 hp (22.4 kW) vector drive, 10,000 rpm, inline direct-drive spindle with max torque of 90.0 ft-lbf @ 2000 rpm122.0 Nm @ 2000 rpm , 50+1 side-mount tool changer, 1000 ipm (25.4 m/min) rapids, automatic chip auger, programmable coolant nozzle, color remote jog handle, power-failure detection module, 1 GB program memory, 15" color LCD monitor, USB port, memory lock key switch, rigid tapping and 55-gallon (208 liter) flood coolant system,

4th AXIS capable, RENISHAW probing system for accurate, repeatable machining.

ProtoTrack (2 UNITS)

TRAK DPM RX3 Specifications:

-

50″ x 10″ table size

-

31.5″ X axis / 17″ Y axis / 25.81″ Z axis travel

-

5 HP continuous spindle motor

-

40 taper spindle

-

Standard Features:

-

ProtoTRAK RMX CNC integrated into the machine at the factory

-

Solid ram moves along the column providing mass for heavy cuts

-

Generous Z-axis CNC travel

-

Strong and rigid

-

Efficient for any job: manual, 2-axis CNC or 3-axis CNC

-

Standard electronic head for programmable spindle speeds and tapping

-

Precision ground ballscrews installed in the table, saddle and column

-

Manual quill with integrated quill and ram encoders

-

Wide way surfaces are hardened and ground, slideways are Turcite® coated

-

Real handwheels so you can work manually

Renishaw

Renishaw

Our shop here at Precision Machining Solutions, Inc. is equipped with latest models of Renishaw OMP probes, providing us the necessity of making the most accurate pickups when machining part details on our CNC machines. Including broken tool detection, component set-up, in-cycle gauging and first-off component inspection, with automatic offset updates. Renishaw probes can help reduce setup/inspection times by 90%, and help improve the process control, and add to the main goal, which here at PMS is to deliver the highest quality products, on time, under budget, while maintaining safety at the highest level.

4TH AXIS ROTARY HRT210HT

The Haas HRT210HT rotary table uses a high-torque servomotor to provide 385 ft-lb (522 Nm) of spindle torque for heavy cutting – that’s 83% more torque than our standard HRT210. This rugged, heavy-duty table can be mounted vertically or horizontally, and chucks and fixtures can easily be bolted to the table using the six precision T-slots and center through-bore